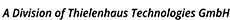

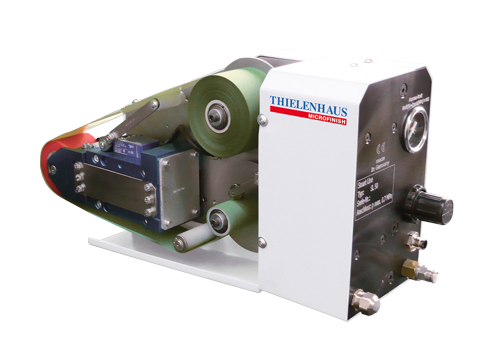

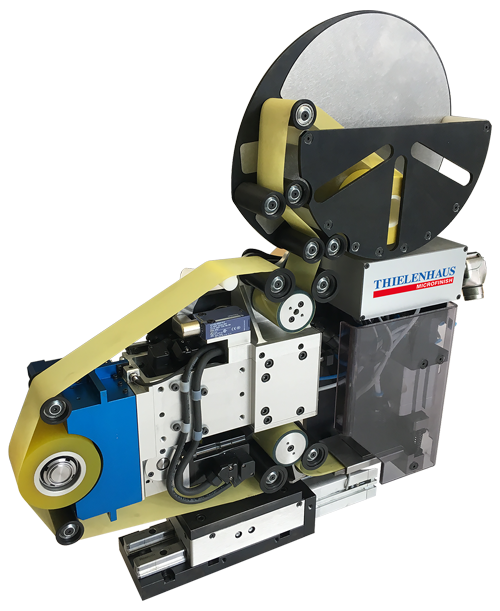

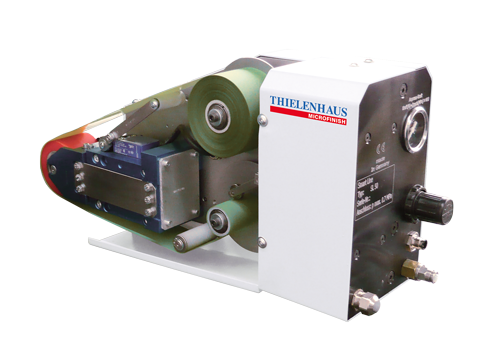

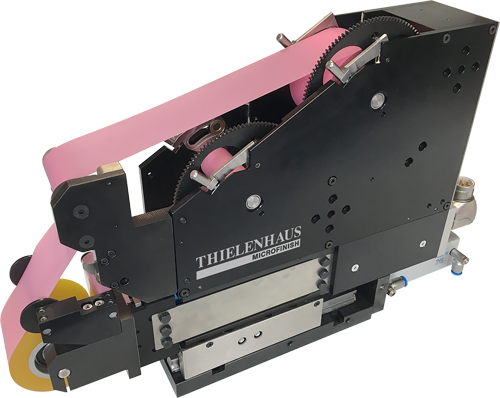

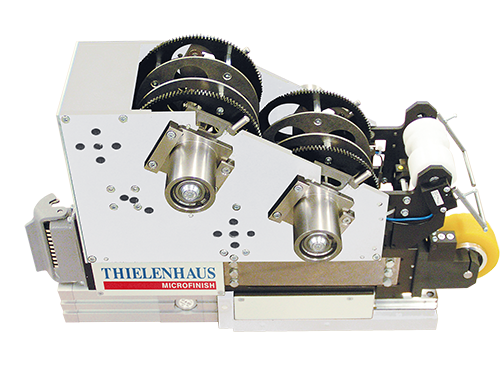

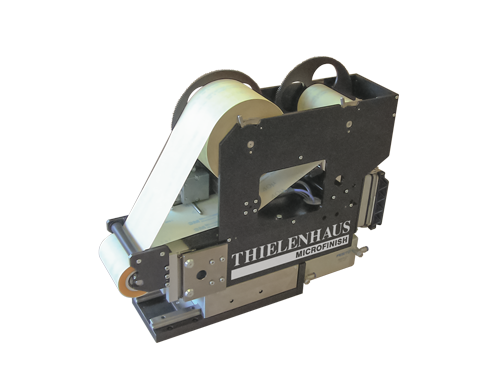

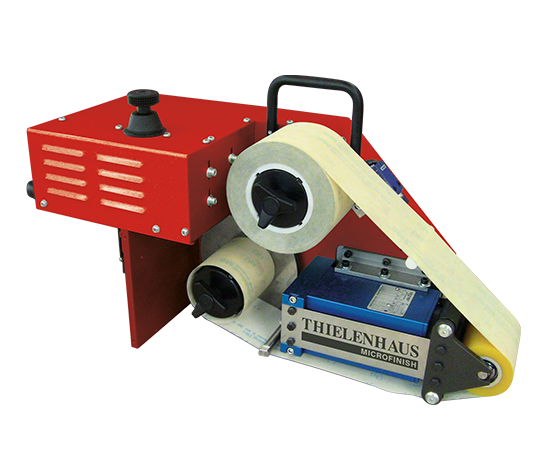

Tape finish and stone finish devices

Microfinish attachment devices provide you with the option to cost-effectively apply precision machining methods to individual parts, small batches and prototypes using an existing supporting machine, e.g. a lathe or grinding machine, and thus to achieve high-quality surfaces and geometric improvements on gear shafts, rolls or piston rods, for example.