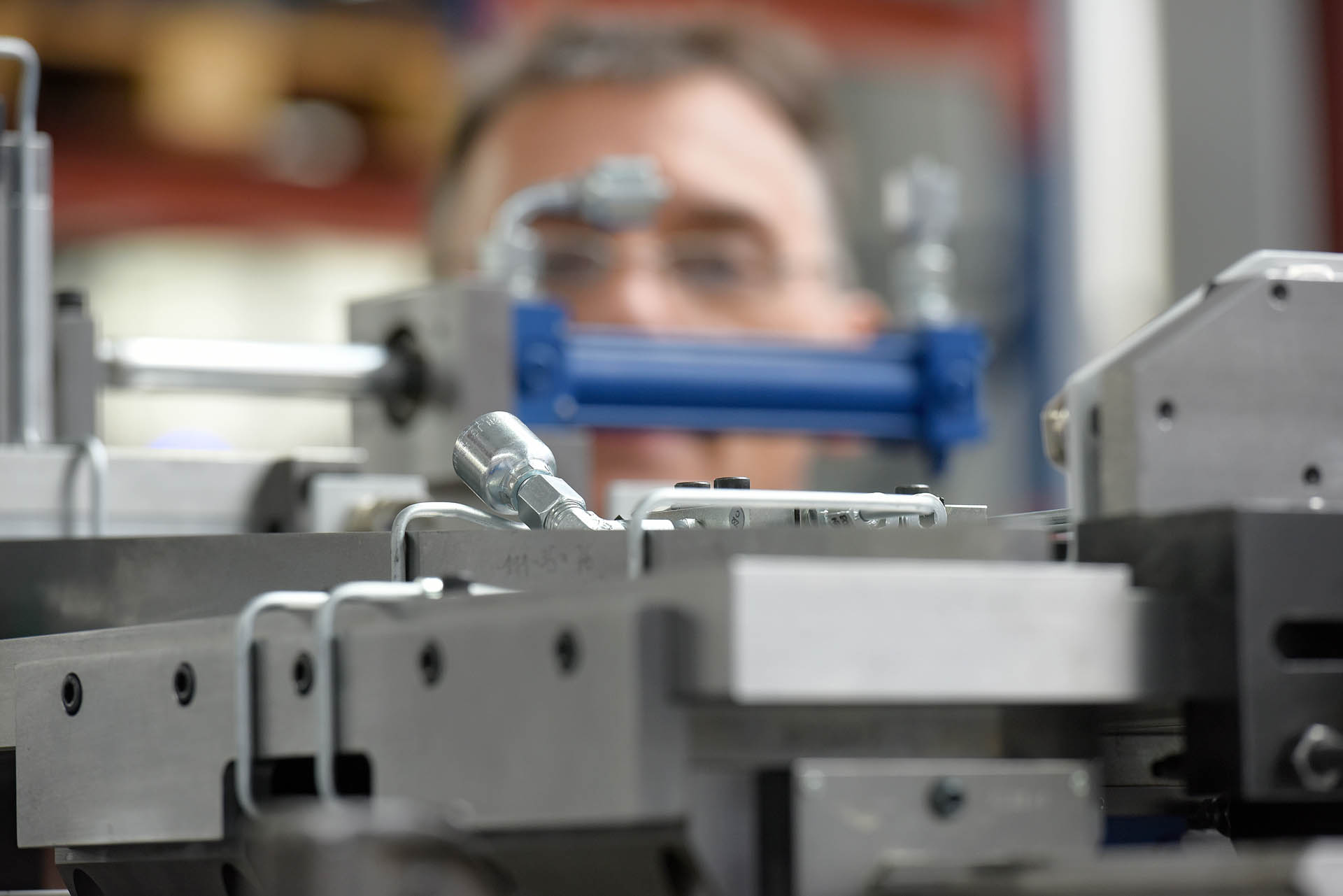

We help sustain your production

Machines are subject to extremely demanding operating conditions, especially in a multi-shift production set-up. Production maintenance is the most important objective when it comes to ensuring continuous manufacturing. In order to safeguard this, we use parts and components from selected suppliers which are of the highest quality and which require minimal servicing.